I just printed the new snap fit Prusa x ends, and ran into a few problems.

The red highlights are where the part cracked under stress. First from inserting the smooth rods, then along the holes for the zip tie, when I pushed in the top lm8uu bearing.

Print settings

This is printed in white PLA from Ultimachine @200 deg C. Nozzle is 0.5mm, layer height is 0.35mm, it has 2 extra shells (thus 3 in total) and infill of 30%. I believe the problem is the flexible part of the push fit design, which doesn't flex at all. I don't know whether it's because of the brittle PLA, or if it can be avoided by using either fewer or more outer shells. Heating the part before inserting the smooth rod will probably help, but

If this is a problem with PLA, I hope there will be an option to switch out the push fit with m3 nut and bolt. Looking forward to having a look at the OpenSCAD files!

Blame the user

The crack along the lm8uu holders is most probably my own fault, it was a tight fit, and I did manhandle the bearing quite a bit. There are some small lips to hold the bearing in place (in the z direction) and the bridge did sag a tad so the bearings didn't fit very well under the top ones. You can sort of see it in the second picture. Using 100% infill might solve this, as moving the holes up would just move the weak spot.

Edit 2011.07.11 :

I just printed the x-end idler, and the bearing holder snapped when I pushed in the bearing (had to use a wood clamp, it was that tight). This trouble might be my printer drawing outside of the lines, instead of on the inside. I'll be back with more info.

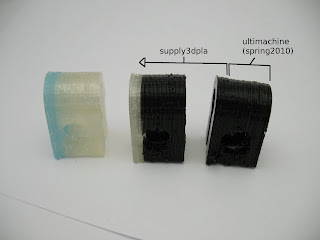

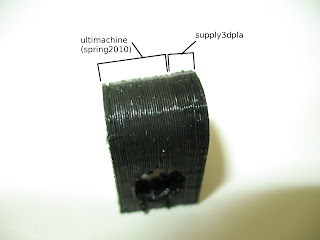

Difference in PLA?

This is the first object I have printed in this white PLA, and it might need a little skeinforge tweaking to get perfect. It seems to flow more, and thus pushes out more plastic than with the other Ultimachine PLA I have. (Silver, transulent blue, natural and black).

For this print I tried to drop the speed from 60 to 55mm/s, and on the x ends, it didn't loose enough y-steps to ruin the results. I have a theory it might be the weight of the plastic spool keeping the maching from rattling, anyone else experienced this? I still can't print gregs lm8uu x-carriage properly though.

New hot end review on the way

While I'm blogging, I might as well drop in a picture of a nice little puzzle I got in the mail:

It's an Arcol 0.35mm hot end, which I'm looking forward to try out. One thing I'm a sceptical about is the hot end relying on threaded PEEK to hold the pressure. People have a lot of good of things to say about this design, but to me a push-fit version just seems a the "safe" way to go. Also, it's a bit large to fit on gregs lm8uu x-carriage, so I have to figure out which printer to put it on, as it won't fit on Adesina now.